We are very pleased to announce another cooperation: iCombine now supports the leading model factory 4.0 to accompany the digital transformation with a new use case in a real production line. From now on, employees of the Digital Capability Center Aachen can use our iCombine software to demonstrate the advantages of dynamic workforce management to their visitors.

Applications for the industry 4.0

The Digital Capability Center (DCC) is a learning center for digital process technologies and future-oriented supply chains. It was founded by McKinsey & Company and ITA Academy GmbH in cooperation with leading technology partners and innovative startups. All participants pursue the goal of supporting the industry in its transformation towards digital manufacturing – from piloting and scaling to continuous optimization. Therefore, a model factory with real machines, products and operators has been established in Aachen, Germany. Within the framework of this unique demonstration environment and in various workshops, visitors (approx. 3,000 – 4,000 per year) are introduced to the latest technical possibilities and necessary measures of an automated production. The resulting new requirements for internal management and employee organization are also brought into focus by the DCC. This is where iCombine comes into play as a selected partner.

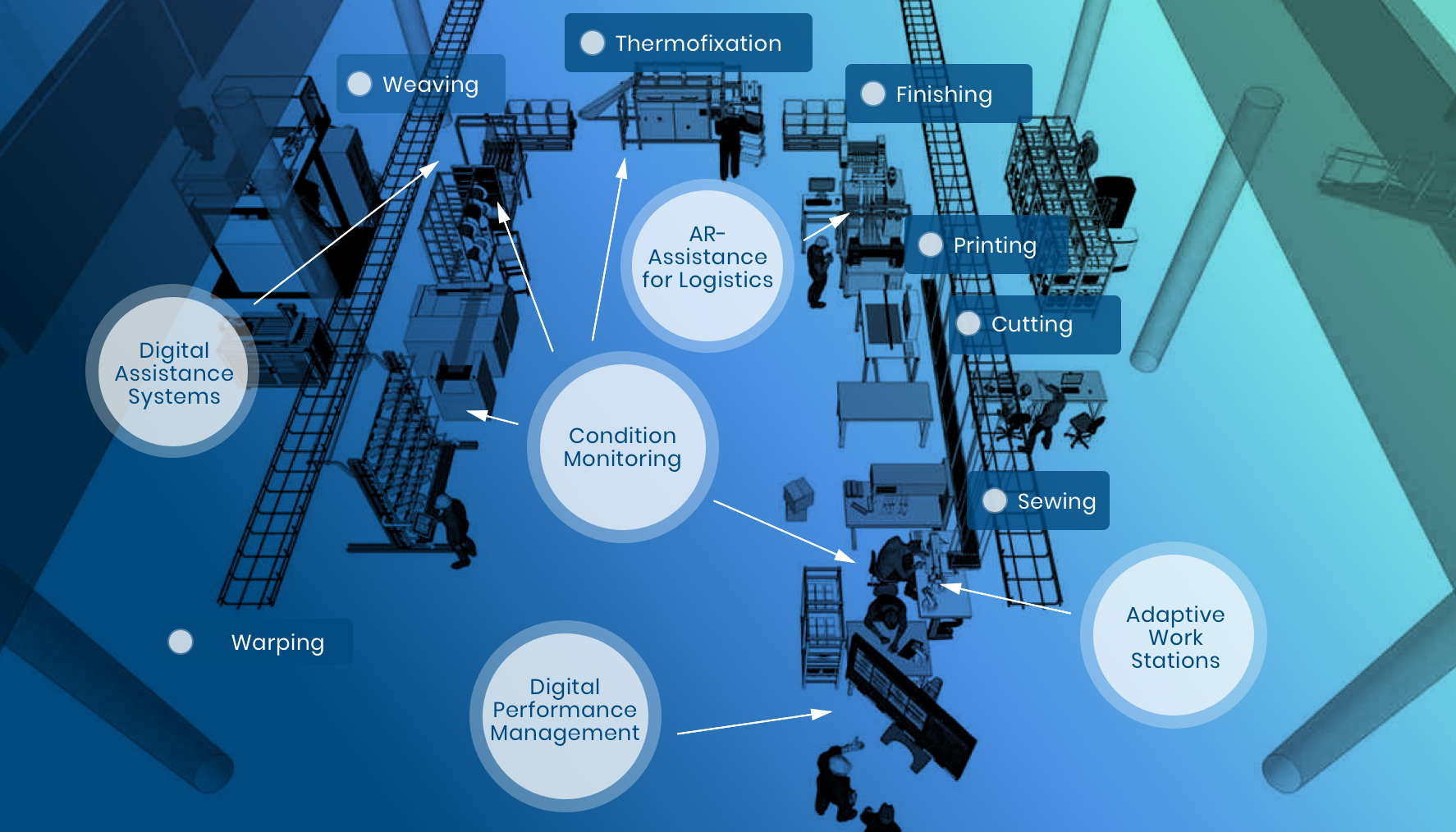

Every process step in the production can be improved by technology of the DCC partners. Source: ITA Academy GmbH

Our cooperation

During our visit of the Hanover Fair 2019 we became aware of the DCC Aachen and its pioneering role. After getting to know the team at the exhibition stand for the first time and the subsequent discussions, all participants recognized the common potential for cooperation. In August 2019 we finally had the opportunity to visit the DCC in Aachen personally in order to design the use case.

Together with the DCC experts, we analyzed the special challenges of personnel planning in manufacturing companies:

-

Source: ITA Academy GmbH

in individual production steps, the competence requirements for employees are very specific

- occupational safety: above all, expertise in the operation of machines must be guaranteed

- staff planning is very time-consuming, as it is often still done with paper documents, Excel sheets and telephone arrangements

- employees should be given further training on the basis of their own interests and in line with production demand in order to retain them in the company

- knowledge about the current planning status and employee competencies often depends on only a few people – their downtime would be very critical

- the company wants to be able to demonstrate the qualification of its employees to the customer

Workforce planning for industrial companies

iCombine provides the following advantages as a solution approach in workforce deployment planning:

- information about the qualifications and availability of employees is visible in a structured way and can therefore be communicated

- requirements for the individual positions in the production chain are simply defined; with the help of matching, operational planners immediately identify suitable employees

- knowledge transfer: employees with different levels of knowledge can be combined and work together in teams

- in case of absence of individual employees, qualified replacement is found immediately

- involving employees in the planning process enables faster coordination and thus higher efficiency

- qualification needs and interests are quickly identified

- personnel planning can be delegated to other people quickly and easily without loss of information

During workshops, DCC visitors will learn about the problems of conventional processes on the shop floor. By means of practical examples and tasks, they will also learn how planning and production can be optimized using technology. We are extremely proud that our application is presented here using a real planning scenario. If Aachen is a little further away from your place of work, please do not hesitate to get in touch with us. We would be happy to present the advantages of modern planning processes to you in a virtual meeting.

The DCC offers public and individual workshops. If you are interested in participating, please visit the website of the ITA-Academy.